Keeping Your Preconditioner Clean

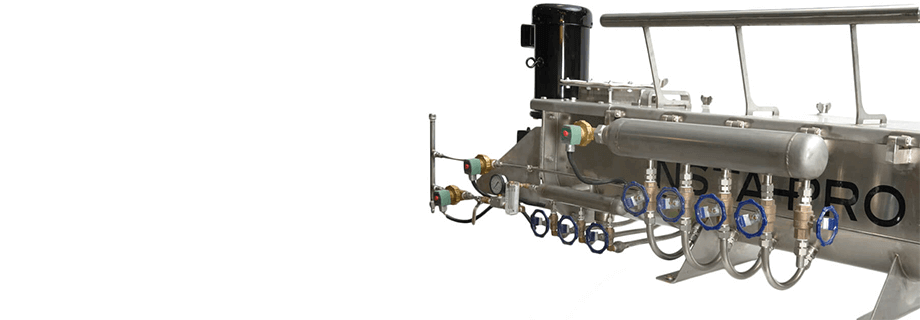

If you own an Insta-Pro extruder with a preconditioner you know it requires maintenance. The preconditioner is a blender vessel with a main shaft and adjustable paddles designed to maintain a specific dwell time before feeding into the extruder. Steam and sometimes water are injected into the conditioner vessel with ingredients to start the cooking process. The advantages of using a preconditioner are having better shapes in the end product and increased capacity.

Since steam and water are used, if the preconditioner sits idle, mold growth becomes a major concern. It is considered acceptable to let the conditioner sit overnight without cleaning, but if it sits for longer than 10 hours, we recommend a complete cleanse of the conditioner vessel, including the inlet and exit ports. Periodic environmental swabbing, or sampling from the preconditioner, to test for the presence of indicator bacteria or molds should also be conducted to ensure that the cleaning procedures are working based off of the manufacturer’s standards. Cleaning your preconditioner can be a messy job, but it must be done correctly to discourage mold growth. The following step-by-step instructions explain how to properly clean your preconditioner to avoid mold growth and ensure proper maintenance:

- Always make sure you lock out the power before preforming any work on the machine

- Shut down the machine and open the door. By exposing the inside of the conditioner vessel to the air while the main shaft and paddles are still hot, you get a drying effect of the product that has built up in these parts

- Disconnect the mass flow feeder and remove the inlet plate that attaches it to the top of the conditioner vessel. This allows for easier access to the inlet side of the vessel

- Remove the transition at the outlet of the vessel

- Using a putty knife, scrape down as much of the built up product as possible into the bottom of the vessel then use a vacuum to remove the loose product. Make sure to scrape everything, including the paddles, sides and top of the conditioner vessel

- Wipe down the conditioner parts with water and bleach dilution, following recommendations from the bleach manufacturer, then allow it to dry. This last step is very important to prevent any mold from getting started. Cleaning with only water is not sufficient to assure a sterile environment

Cleaning has always been, and will always be, an important part of assuring a high quality end product and durable equipment. This doesn’t only apply to the preconditioner, but the whole production line. All pre and post handling equipment, conveyors, cleaners, milling, cooling and drying, and packaging should be inspected and cleaned, but the how often depends on the end product you are producing, how long you run your machines and any state or federal regulations that exist in your area. Yet, if at any time, your machines are down for more than 24 hours, they must be completely cleaned out. Look out for our blog on quality control for additional information on cleaning out your production line. To learn more about equipment cleaning and maintenance, contact our service team.