Preserve Your Nutrients – Don’t Bake Your Product To Dry It

In a previous blog post, I discussed the differences between dry and wet extrusion, and the relative moisture loads that must be dealt with after extrusion for food processing for product preservation. As I mentioned, drying is typically done with large, heated, conveying dryers to remove moisture.

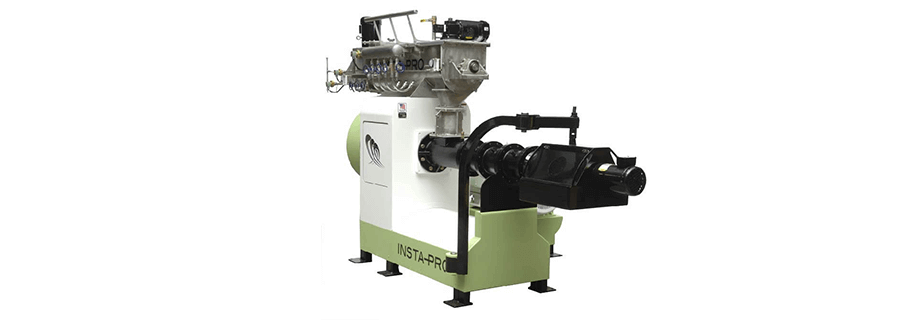

Insta-Pro’s new Medium Shear Extruder is targeting quality-minded producers of shaped, dry products – most notably, dry pet food and fish feed for aquaculture. The purpose of any food or feed product is to provide a source of high-quality, balanced nutrition – nutrients that promote growth and health in animals. Examples of nutrients include protein for muscles, fat for energy to do work, and vitamins for a healthy immune system. From harvesting raw ingredients, to mixing and processing, and finally, storage of finished products, each point along the way provides an opportunity to change the quality of the final food product.

This leads us back to my previous blog – the more moisture present after extrusion, the more moisture that must be driven off with heated drying. Insta-Pro’s Medium Shear Extruder uses dry extrusion technology and less moisture for cooking – hence, less moisture must be removed.

This is important because heated drying has detrimental effects on nutrients – more heating results in a lower quality product. Researchers at Wageningen University in the Netherlands studied the effects of several factors on nutrients in dry dog food, including drying (Tran, 2008). The researchers reported that when drying dog food (beginning at 30% moisture) at higher temperatures, several changes were noted:

- With smaller (4 mm) sized dog food, elevated drying temperatures reduced concentrations of some amino acids (critical building blocks of protein):

-Lysine was reduced 18%

-Reactive lysine was reduced 27%, an indication of damage from heating. - Also with 4 mm dog food, unsaturated fatty acids (nutritionally-important components of dietary fat) were reduced, while saturated fatty acids were increased, at higher temperatures used for drying – the authors noted that this could indicate fat oxidation, or deterioration of the dietary fat.

- With larger (8 mm) dog food, reactive lysine was reduced by 10% with heating for drying.

- It’s also interesting to note that several key nutrients were not measured in this study (which is common of nutrition experiments), for example, the heat-sensitive vitamins.

In conclusion, Insta-Pro’s Medium Shear Extruder uses less moisture to make shaped, dry products – dry pet food and fish feed – and as a result, requires less heated drying after extrusion. A high-quality, finished product (an excellent source of nutrients for animals) can be created with our new Medium Shear Extruder.

See also: Tran, 2008. Extrusion processing: effects on dry canine diets,

Ph.D. Thesis, Wageningen University and Research Centre, Wageningen, the Netherlands.