Mechanical Soy Processing: An Environmentally Friendly Method

Articles have appeared in various local newspapers over concerns raised by communities regarding the negative environmental impact of soybean processing plants that use a chemical process to extract oil from soybeans. The specific concern relates to the resulting emissions of high levels of volatile organic compounds (VOC’s) which are a by-product of the process.

Whereas this method of soybean processing is commonly used for large scale centralized plants, it is not the only method.

Mechanical processing methods, which are chemical free, existed prior to the wide spread use of chemical processes which were adopted based on ability to remove 100% of oil present in soybeans. Early mechanical methods, used presses to “squeeze” the oil from the soybean, however oil extraction rates were 50% at best, and often times generated excessive heat causing damage to the vital nutrients.

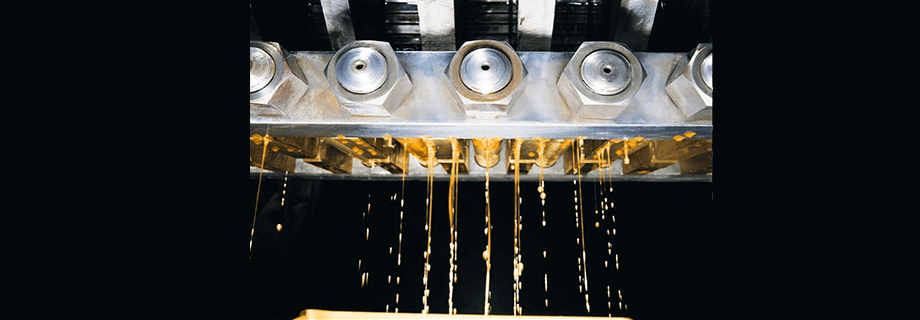

In late 1980’s Insta-Pro introduced a branded process called ExPress® (Extrusion Pressing), which coupled the High Shear Dry Extruder with Continuous Horizontal Oil Press. The ExPress® process capitalizes on benefits of using extrusion to fully cook, deactivate anti-nutritional factors and rupture oil cell walls in a short time without the use of chemicals. The process allows for extraction rates up to 70% resulting meal of 46-50% protein and 6-8% fat, with without use of chemical or prolonged heating process.

This method has been adopted worldwide with crushing plants ranging in size from 10 to 1200 ton per day and it has become the method of choice by processors of organic and identity preserved seeds.