Wet collectors for steam exhaust

In a previous blog, we mentioned the various principles of steam exhausting. One of those was how to handle the discharged vapor. Most places can allow this vapor to be exhausted straight out of a building without any consideration. If there are any concerns about where this vapor will end up, however, there needs to be a method to handle the vapor. One of the most effective is known as a wet collector.

Working principle

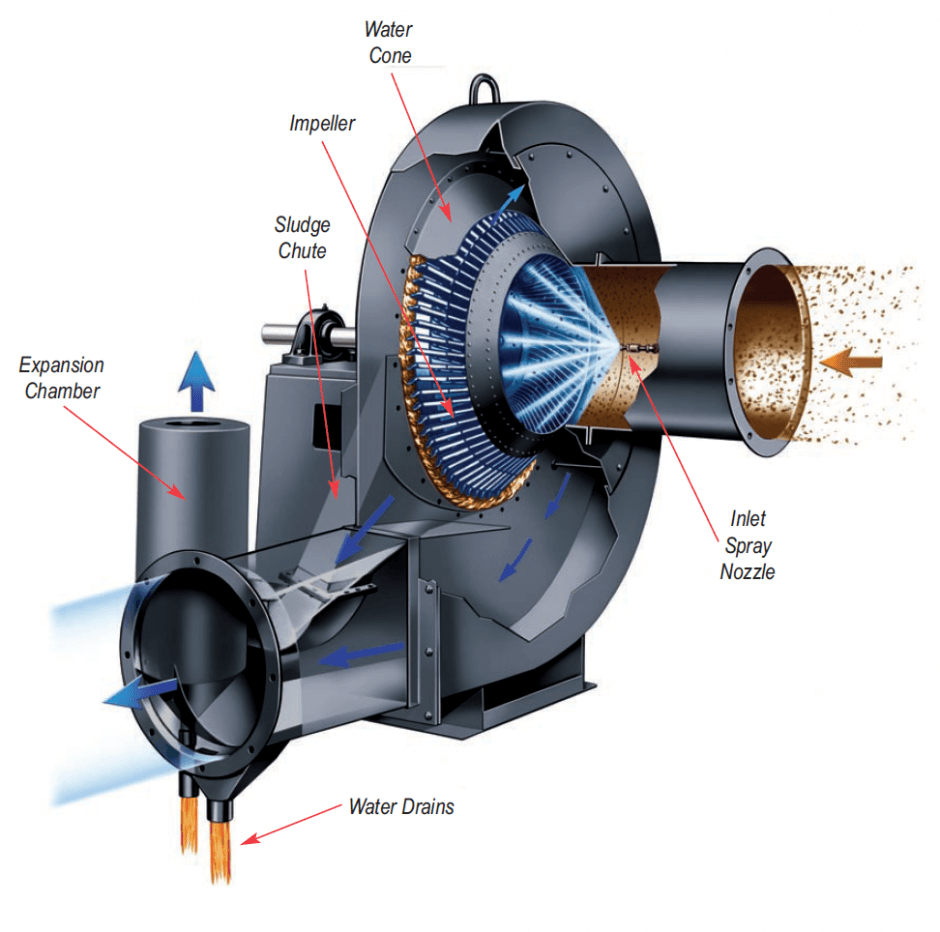

Wet collectors operate by combining the collected vapor stream with a misted wall of water. The collector itself is essentially a large radial fan. This fan is sized according to the steam exhaust needs and is how the vapor is removed from the respective area. Just before the fan, there is a small nozzle which generates a small cone of mist from water. As the vapor contacts the mist wall, any particulates contained within the vapor combine with the mist and are discharged into a waste water stream.

Advantages/Disadvantages

The wet collector is a very effective means of controlling exhausted air, especially when it contains particulate matter such as oil and solids. This creates a clean environment and is likely the best choice for applications that demand it.

While the positives are beneficial, there are two main downsides. One is the cost. Wet collectors can be expensive and are a significant investment. For smaller applications, the investment costs may not be feasible. Additionally, there is a reoccurring cost of water and waste water to consider. Environmental requirements will dictate if a wet collector is needed, but when they are, they are a tried and true solution.

As always, we are happy to work with you to help define the best solution for your processing plant.