Die Land Length

When it comes to producing quality pellets for fish feed and pet food, there are several factors that you must consider that can control the final product you produce. During the process of developing either pet or fish food, one of the final interactions of your product occurs at the cutterhead. Dies are used to create the various shapes and sizes of products. The design of the die has a great impact on the end product outcome. One major factor of design that can affect the quality of your end product is the land length of the die. This single dimension can control whether you produce a floating or sinking fish feed or a very airy or dense pet food pellet.

What is land length

The land length of the die is the dimension of the straight section within a die. For denser pellets, this dimension is longer and for lighter pellets, this dimension is shorter.

During extrusion, the product is under several pounds of pressure within the barrel. As it passes through a die, the pressure increases even more to several times atmospheric pressure. The sudden contact with the outside ambient air causes a massive drop in pressure, causing a large expansion to occur within the pellet. This is generally true unless the pellet has had long enough to form into a dense product. If this pressure occurs quickly (relative to overall die geometry), the final product tends to puff into a light pellet. However, if the product is forced through a die for a long time (relative to overall die geometry), the final product will have little expansion and create a dense pellet.

Application

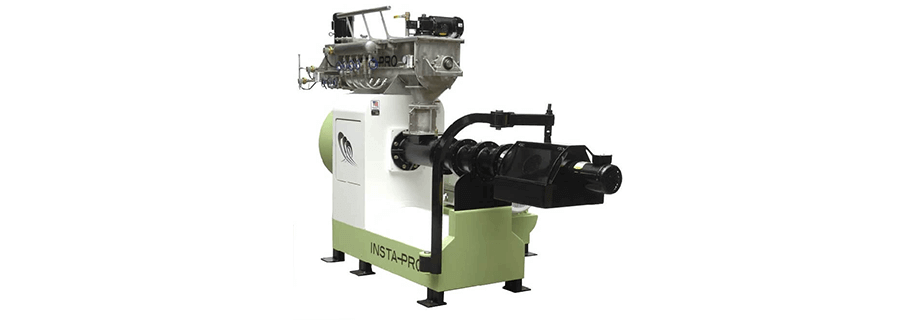

Knowing how the land length affects the final product can help in your production and will be most beneficial to understand what is going on if you are not producing the final pellet you need. If your pellets need to float and are not, it could be that the land of the die is too long. On the other hand, if you need to maximize pellet density and cannot, your land may be too short. This could also tie into the number of dies on the plate as well, but if temperatures seem good, the land may be an area to consider. It is critical for all shaped feed businesses to work with equipment suppliers that understand die design to optimize to your end product goal. For Insta-Pro customers, our engineering team would be happy to help if you need assistance with die development.