Mechanical Oil Pressing

Oil extraction is often a goal with seed processing. Oils can be harvested from a variety of seeds and a common method is through an oil press. This differs from crushing since the seeds are sheared against small openings with a screw as opposed to pressing seeds in a squeezing type action with a cylinder. Another method is to use chemical extraction (i.e. Hexane). Mechanical oil pressing is a cost efficient, versatile and chemical-free method that allows one to process oil seeds easily.

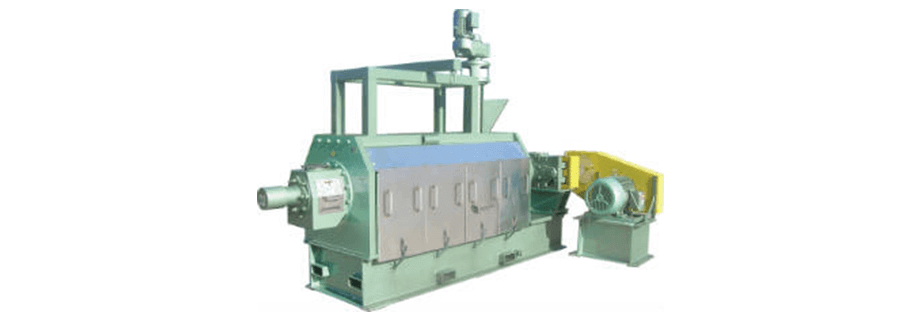

The typical oil press features three important parts: the cage, screw, and cage bars.

Cage: This assembly houses the screw and cage bars. As seeds pass through this section, oil seeps out into the oil reservoir below. Some solids pass through as well and are pumped out with the crude oil.

Screw: This conveys the seeds through the press cage and against the cage bars. The action of the seeds being conveyed against the cage bars squeezes the oil out of the meal. When the meal reaches the end, the cake falls out and is conveyed to the next process. A motor is used to drive this screw.

Cage bars: These bars are spaced very closely together and form a ring around the screw. When the cage is closed, these encircle the screw. As mentioned above, these work with the screw to help shear and press the oil out of the seeds.

There are other ways to expand oil processing as well. Extrusion may be able to increase press efficiency and yields by allowing oil cells to rupture, making the oil easier to access and remove. A great example of this is the Insta-Pro ExPress® process. In the case of soybeans, this process is able to extract up to 66% of the available oil out of the seed. Other seeds can be processed in this manner as well. Oil pressing is just the beginning, and with the proper equipment and guidance, you will be able to process efficiently and chemical-free.