Vented conveyor length

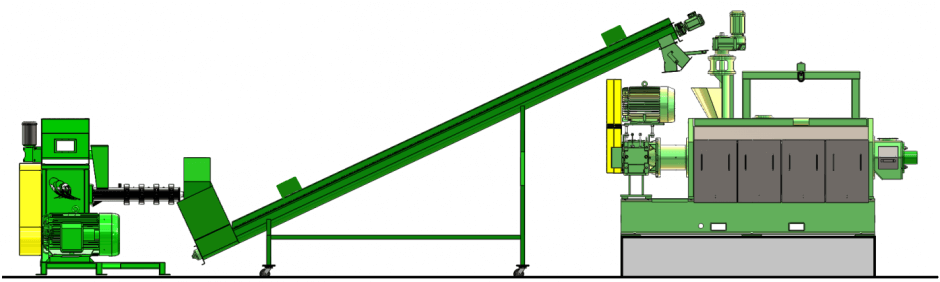

When designing an ExPress® line, there are many things to consider. It’s a little like putting together a Lego® set where you can build pretty much whatever you want, so long as you have the correct pieces. One of these pieces is the vented conveyor that transports the extruded full fat soy into the oil press. The length of this conveyor is critical and is very dependent upon the layout.

Factors to consider

When designing the ExPress® plant, the final capacity needs to be noted. This depends on the number of oil presses being used. Typically, these presses discharge into a collection conveyor which transports this meal to cooling. As the capacity grows, so does the size of this conveyor. At a certain point, the diameter of the conveyor becomes taller than the discharge height of the oil press. Because of this, the press itself must be raised on a platform or the conveyor must be lowered into the ground. Our general advice is to build a platform that raises the press high enough so that it can discharge correctly into the conveyor. This creates the need for a longer vented conveyor between the extruders and press.

Typical size ranges

The length of conveyor used will depend on the type of oil press used. Our vented conveyor stand is designed to maintain a constant conveyor angle for better product flow, so in order to reach a taller height, the conveyor length itself must increase. The table below shows some typical conveyor length values depending on the stand height of the oil press.

| Press model | Stand height | Conveyor length |

| 2000 | None (on ground) | 15′ (4.75m) |

| 2000 | 12″ (3m) | 20′ (6.1m) |

| 5005 | None (on ground) | 20′ (6.1m) |

| 5005 | 12″-24″ (3m-7.3m) | 22′ (6.7m) |

| 5005 | 30″ (9.1m) | 25′ (7.6m) |

The size of the stand will depend on the diameter of the discharge collection conveyor after the press, but this will depend on the final plant capacity. As you can see, conveyor length is just another piece of the puzzle when it comes to plant design.

We encourage our customers to take advantage of our years of experience with oilseed crushing plants. We can help you with the “puzzle” to optimize and expedite your plant design.