Insta-Pro International + Desmet

Partnering In Extrusion-Pressing Systems

Take operations to the next level with precision-crafted extrusion-pressing, ExPress® Systems, from Insta-Pro Intl & Desmet. With over a century of combined processing expertise, our partnership optimizes efficiencies in oilseeds & grains to improve nutrition for producers of meat, milk & eggs.

The Collaboration

Developed by Insta-Pro International, The ExPress® Processing System, extrusion-pressing, utilizes high-shear dry extrusion for oilseed processing combined with screw press oil extraction under precise time, temperature & moisture conditions.

Insta-Pro Intl

- World leader in soybean high-shear dry extruders

- Established ExPress® System trade secrets & brand

- Expertise in extruded ingredients since its invention in 1969

- 50+ years of university research verifying improved nutritional values & improved animal performance

- World leader in oilseed crushing plants meeting the needs of large-scale soybean processors

- Desmet Rosedowns specializes in the design and manufacture of screw presses for oilseed processing

- Rosedowns, a proud member of the global Desmet organization, has a rich history dating back to 1777

- +3,500 presses in more than 100 countries

Insta-Pro Intl – Desmet

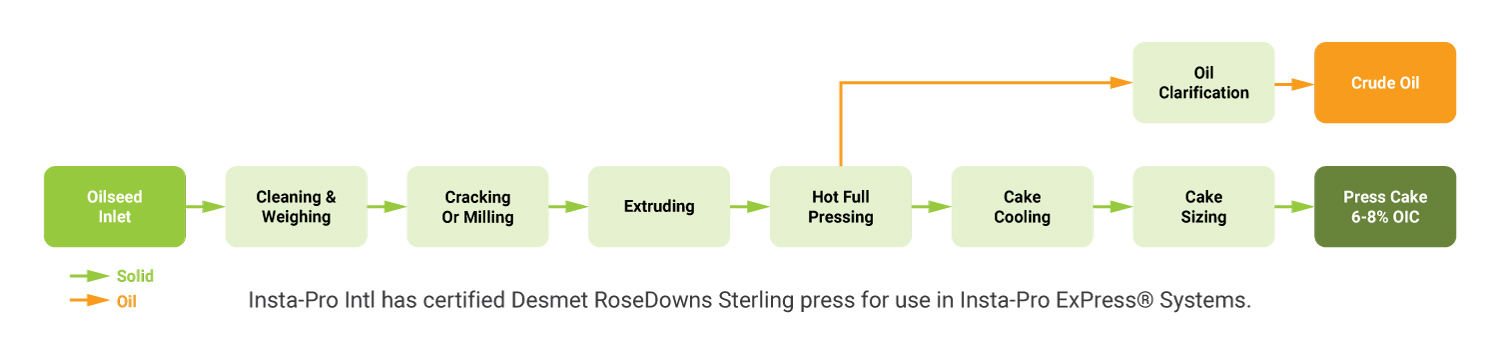

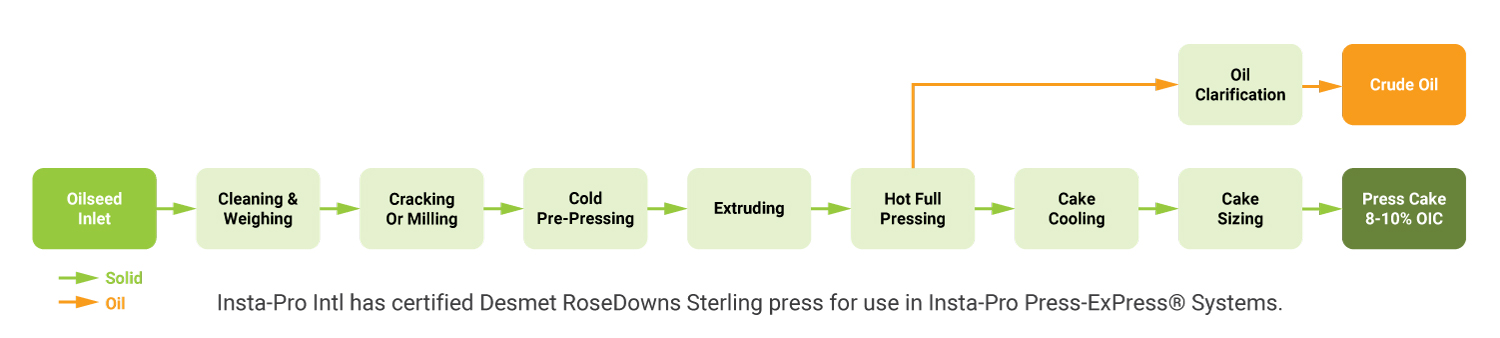

Collaborating to bring industry leading expertise & equipment solutions for large scale processing soybeans and high oil bearing seeds, such as sunflower & rapeseed. Insta-Pro Intl has certified Desmet RoseDowns Sterling press for use in Insta-Pro ExPress® Systems.

How Does It Work?

High-Shear Dry Extrusion

Raw oilseeds enter the extruder and undergo severe mechanical shearing, exiting the extruder a complete rupturing of plant cells occurs. This process turns raw oilseeds into full-fat meal, a flowing outlet material with easily available oil. The high-temperature/short-residence-time in the extruder is critical, ensuring optimal deactivation of anti-nutritional factors while increasing protein digestibility.

Oilseed Pressing

Once in the screw press, the friction placed on the full-fat meal inside the press cage will allow for maximum extraction rate ending up with ExPress® press cake/meal as low as 6% residual oil. ExPress® meal is a nutrient dense feed ingredient known for its increased performance in the production of meat, milk & eggs.

Foots Recovery & Oil Clarification

Oil recovered at the outlet of the press contains suspended solids. After the decanting stage, where most of them are removed, the oil is filtered and cooled before storage and decanted solids returned to meal stream.

Cake Cooling

The hot cake, discharged from the press & is cooled before storage in a vertical or horizontal cooler using counter-current airflow.

Species Benefits

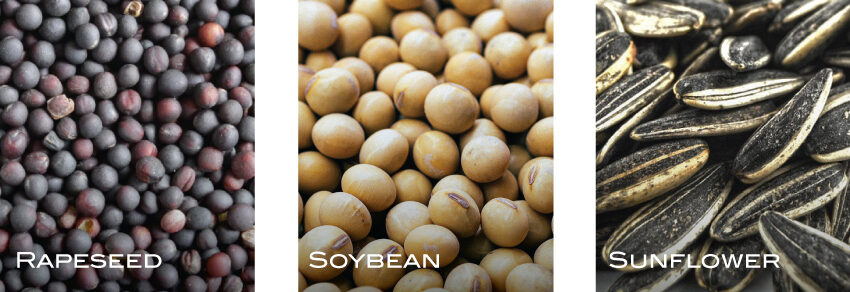

Raw Materials

Besides soybean, extrusion-pressing of high oil-bearing seeds like sunflower and rapeseed remains the most efficient solution for solvent-free, steam-free extraction. This process encompasses pre-press stage followed by the ExPress® System.

ExPress® System - Soybean Meal

Press-ExPress® System - Sunflower & Rapeseed

Advantages

![]()

Equipment

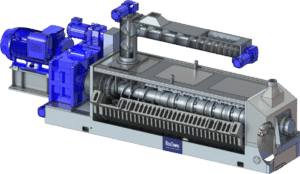

The ExPress® System couples a high-shear dry extruder from Insta-Pro Intl and Desmet RoseDowns Sterling press, specifically designed to reduce anti-nutritional factors while keeping protein integrity in ExPress® meal, resulting in high-oil yield and enhanced protein digestibility.

|

|

|

| 9000 Extruder | Sterling Series Press | |

| Insta-Pro Model 9000 high-shear dry extruder maximizes oil-seed product value. Ideal for organic, specialty and identity-preserved oilseeds. The Insta-Pro Intl extruder is an innovative, chemical-free processing solution providing a nutrient-dense product with exceptional ROI for producers of meat, milk and eggs. | The innovative design reflects years of RoseDowns, a subsidiary of Desmet, industry expertise, with the Sterling Presses offering exceptional pre-press and full press performance across various throughputs. |