Mechanical Presses: Don’t Be Mistaken, Quality Matters

At a recent Tradeshow I attended, I was speaking with a current customer who had purchased extruders from our company, but operate local, inexpensive presses with them.

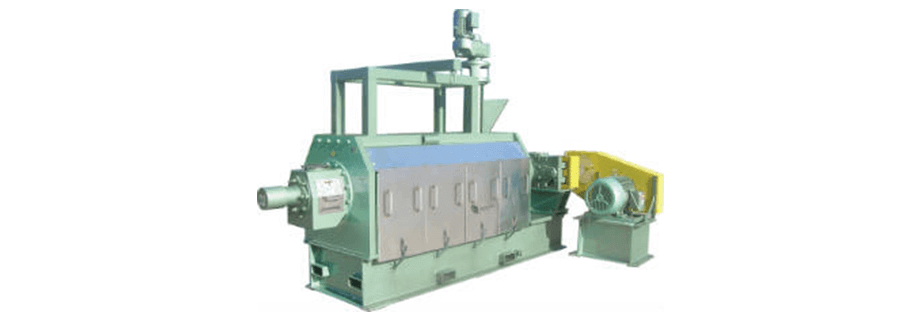

While the quality of the full fat coming from our high-shear dry extruders was excellent, he admitted that he was having problems with the presses. The issue was that he would do maintenance on the presses with new components, but within two weeks his residual oil content rose 2%. This was significantly impacting his profitability as he was losing the premium he got from the oil versus selling the meal. The high wear was also causing increased maintenance, costing him production time and real money. (Note: Insta-Pro presses operate 1000’s of hours before parts maintenance is required)

In addition to shutdowns and part expenses, this was also impacting the specification commitments to the customer on his meal. When the oil content is higher than specified, he will start to lose meal customers because the meal inconsistency negatively impacts the diets of the animals. Animal diet formulations are designed to meet specific nutrient requirements. When the nutrient requirements are met, growth performance & efficiency can be maximized. It’s very challenging to do this when ingredients vary in nutrient composition and quality.

The other area he may not be aware of is all presses are not designed with the same end goals in mind. Our presses are designed to remove the oil with very little cooking as the meal is already optimally cooked through the extruders. With additional cooking, he could be damaging his protein digestibility.

Now, given these experiences, the customer is in discussions with us to replace his presses. Don’t make the same mistake of just buying Insta-Pro extruders, the quality of the presses really matters! It could make the difference of whether your business succeeds or fails.