Maximizing Corn Ingredients

In recent years, we’ve invested more in and researching the promising applications of our high-shear dry extruded corn ingredient, Hi-Gel™ corn. Materials that are high in starch have posed a challenge for processing by use of high-shear single screw extrusion. But by applying our decades of experience in high-shear extrusion we overcome those processing challenges and developed a unique ingredient – Hi-Gel™ corn. We continue to invest in third party University research as well, to verify the nutritional and animal performance benefits of extruded grains with emphasis on corn.

Corn and other cereal grains are included in animal diets for many reasons, but one of them is because they supply dietary energy. Energy from the diet is needed by the body to perform basic functions and for increased performance of animals used for food.

I previously shared documentation that high-shear dry extrusion is often used to increase the useful or available energy for animals (metabolizable energy). If dietary energy is not metabolizable, it is of no use to the animal. It’s completely lost to the surrounding environment. Therefore, it is of interest to measure the metabolizable energy of high-shear dry extruded corn in order to determine the value of the process.

Data received from recent studies we have conducted with Dr. Parsons’ Lab at University of Illinois indicate the following:

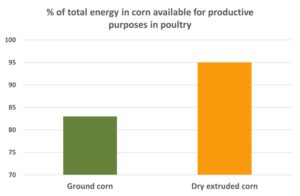

Typically, corn is ground through a hammermill and included in various animal diets. In the above chart you can see, when raw, clean corn is processed through a hammermill. Metabolizable energy value reaches about 83% of the total energy in corn for use in poultry diets (metabolizable energy = useful for production purposes.) However, when the same ground in corn is put through our extrusion process, the percentage of metabolizable energy in corn increases to 95%.

You will see in this month’s upcoming blogs; we have continued to explore new benefits for Hi-Gel™ corn in poultry as well as swine through experimenting with particle sizes.