Hi-Gel™ Corn – Particle Size for Broilers

Hi-Gel™ corn, the product of high-shear dry extrusion from Insta-Pro, is an improved version of the commodity ingredient. Corn starch in this ingredient is thoroughly gelatinized (90% or more), making it easier to be digested and absorbed by animals. This was proven more than useful through a study we conducted with Iowa State University a few years ago. In this study, broilers fed Hi-Gel™ corn exhibited increased feed intake during the starter phase, and the birds achieved market weight faster than when fed ground corn, the commodity version. When a higher-quality version of soybean meal was added to the diet, in this case, ExPress® soy meal, the birds grew even faster and achieved market weight about 4 days quicker.

We are constantly trying to refine and understand our processes, using animal testing as the gold standard for measuring nutritional quality. Recently, we completed some testing to look at the effect of particle size of corn, both raw and Hi-Gel™, on the amount of available energy and digestible amino acids in corn. We worked with the lab of Dr. Carl Parsons at the University of Illinois and his cecectomized rooster assay. Particle size is important for many reasons, including those related to how the dry extruder will operate, and because it affects animal performance as well. We looked at 3 particle sizes (300, 500, and 700 microns) and two states of corn (raw or dry extruded using Insta-Pro equipment). Some of the main findings are shown below (note that the various particle sizes are averaged within each bar because particle size didn’t make any difference).

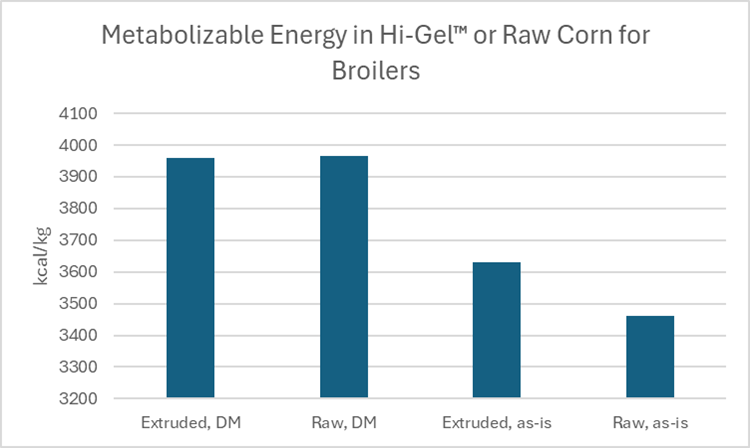

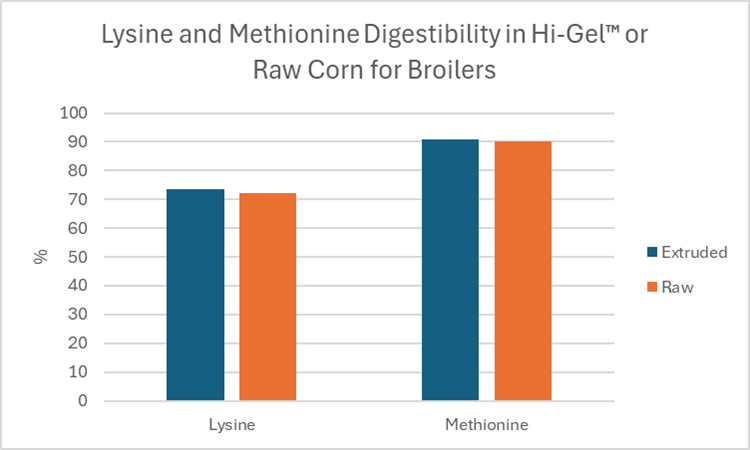

So, according to this new data, Hi-Gel™ corn does not contain more metabolizable energy (i.e., for productive purposes, or ME) or digestible amino acids than raw, ground corn. It’s true that when expressed on an as-is basis, there are about 167 more available kcal of useful energy, but that can all be explained by differences in moisture. Previous blogs have indicated that Hi-Gel™ corn likely contained greater ME than ground corn in broilers, but this was using published data for ground corn – not animal data.

There was very little variation in the metabolizable energy with different particle sizes. As an example, with raw corn that had been ground to 300 microns, the ME values from 4 groups of birds were 3886, 3856, 3921, and 3920 – essentially no variation. When that same particle size was extruded, the values were 3848, 3966, 4043, and 3825 – again, very low variation. The particle size of the corn used in this study did not affect any of the nutrient parameters measured.

So, the data from this recent work helps to point a few things out:

- Animal data of many types is required to understand how an ingredient should be used.

- A feeding study, measuring intake, growth, and efficiency, will give you one set of information; a study to measure digestibility of nutrients, also using animals, will give other information. Both are important.

- Insta-Pro has been conducting both types of studies for over 50 years – no other equipment company has this level of understanding.

Finally, if there are no differences based on particle size or nutrient digestibility, why did the broiler performance trial with Hi-Gel™ corn show such advantages? The most likely reason is that high-shear dry extrusion is causing a physical change to the starch and other molecules in corn, which allows broilers to consume much more corn. As indicated above, a recent feeding study found an increased intake and a quicker time to market weight when Hi-Gel™ corn replaced commodity, ground corn.

Please contact us for further discussions and if you have questions let us put our reservoir of knowledge to work for you!